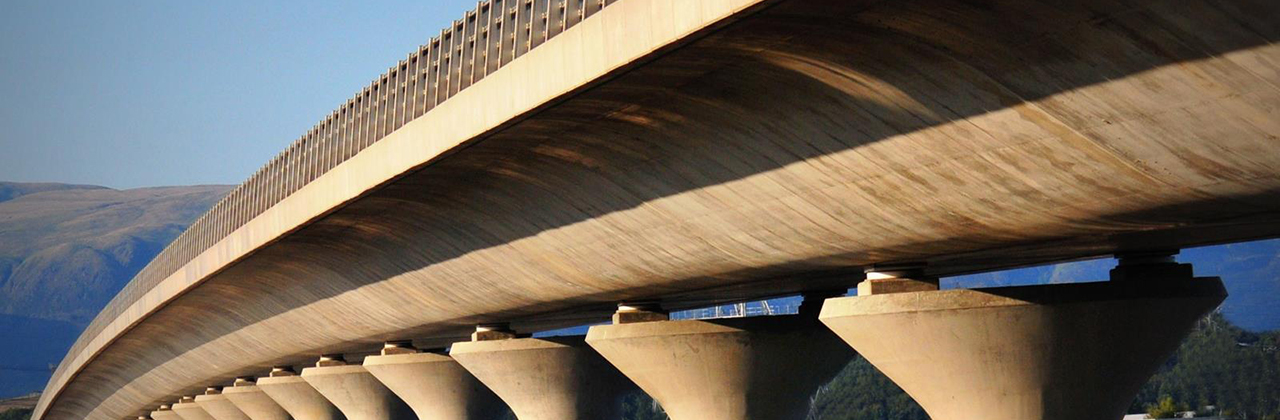

Clackmannanshire Bridge

Project summary

- Bridge project: Crossing point for the A378

- Start/finish dates: 2006/2007

- Bridge type: Pier bridge

- Length:1.2km (50m main span)

- Structure: Multi-span, incrementally launched segments, concrete mono piles (5m dia), cages, hollow column stems

- Production: In situ concrete pour, down -10ºC and pumped up to 850m

- Main Contractor: Morgan Sindall

Product and volume supplied by Hanson:

- Regen (GGBS/Scunthorpe), cement (Ribblesdale), aggregates and concrete (site plant)

- Mix design high workability 4hrs, then rapid strength gain plus “rich mix” glass finish

- CEM I and 70% Regen (GGBS) mixes (durability DC 3/4 ground conditions, environmental aspects, colour, control of heat of hydration)

- Concrete volume 52,000m3

- Regen volume 4,000m3

More about Regen

Regen is Ground Granulated Blast furnace Slag, commonly known as ‘GGBS’.

It is a cement substitute, manufactured from a by-product of the iron-making industry.

Using one tonne of Regen in concrete reduces the embodied CO2 by around 850kg, compared to using one tonne of Portland Cement. It also increases the concrete’s durability and is more sustainable than other cement substitutes such as Fly Ash.

In the UK, GGBS is usually supplied as a separate component for concrete and is added at the concrete mixer.

It can replace 70 per cent or more of the Portland cement. In British Standards, GGBS is referred to as an ‘addition’ and counts fully towards the cement content in concrete.

Regen conforms to BS EN 15167-1 “Ground Granulated Blast furnace Slag for use in concrete, mortar and grout” and is available throughout the UK, accompanied by a full technical and logistical support package.