Has your concrete cracked?

What causes cracks in concrete slabs?

Chances are if you are reading this then you are one of many concrete users or purchasers who unfortunately has experienced cracking.The initial response to cracking is that there must have been something wrong with the concrete when it was delivered.

Not so, the majority of surface cracks in concrete slabs are usually as a result of aftercare.

Ready-mixed concrete producers have two standard answers to this problem: “we produce concrete with cement, aggregates, water and more often than not, admixtures, we do not have a feed bin for cracks” or “there were no cracks in the concrete when it came down our delivery chute”. Both of these statements are true.

Primary causes

The primary cause of concrete cracking is either:

- No curing applied after finishing

- Ineffective curing

Premature drying or rapid drying results in surface tension build up, and this propagates as cracks at the surface. The occurrence, direction and size can vary greatly depending on weather conditions at the time of placement. Ambient temperature, relative humidity and wind speed are all factors either on their own or in combination.

We also get numerous customers who have never cured concrete and never experienced cracks. The truth is that they may not have experienced visual cracks, but there is a high probability that micro cracks have developed although invisible to the naked eye.

In addition, by not correctly curing concrete, surfaces can be as much as 50% less durable and prone to dusting and delamination.

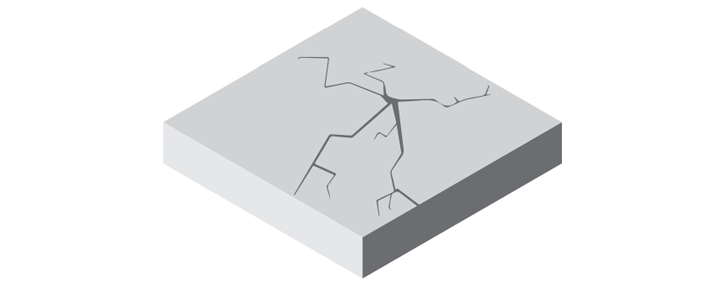

The cracks

The appearance of cracks can occur within a few hours of finishing the concrete although usually they are not visible until the following day. Despite them being at the surface they will develop through the entire thickness of the slab. It is important to note that these cracks (plastic shrinkage cracks) are not classified as structural cracks and do not affect the overall structural integrity of the slab.

If the slab is a direct wearing course (driveway, warehouse, etc) then surface durability may be an issue as detailed above. They can range in width from hairline to a few millimetres. They can occur randomly or appear to be in a pattern.

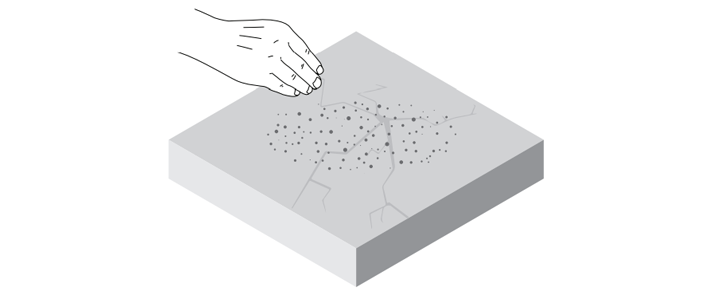

Repair

The most effective way to repair the cracks is to brush dry cement powder over them, the cement fills the crack and residual water in

the concrete will activate it, creating a seal. If left open, water can penetrate and cause further edge and internal damage through the action of freeze thaw.

Effective curing

For more advice on how to cure concrete correctly please refer to our Curing concrete guide.